Phekolo ea bokaholimo bakeng sa profil ea aluminium ke eng?

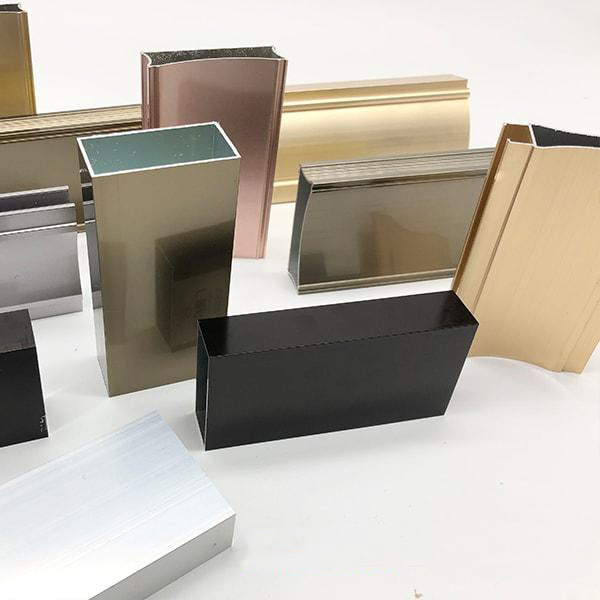

Kalafo e ka holim'a metsi e na le ho roala kapa mokhoa oo ho oona ho sebelisoang ho roala kapa ka thepa. Ho na le liphekolo tse fapaneng tse fumanehang holim'a aluminium, e 'ngoe le e' ngoe e na le merero ea eona le ts'ebeliso e sebetsang, joalo ka ho ba botle bo botle haholoanyane, sekhomaretsi se betere, kapa se hanang ho bola, jj.

Ka ntlafatso e tsoelang pele ea maemo a bophelo a batho, litlhoko tsa ponahalo le mebala ea mamati le lifensetere li ntse li phahama, 'me ka ntlafatso ea butle-butle ea theknoloji ea ho lokisa aluminium, liphekolo tse ling tse rarahaneng tsa holim'a metsi li ntse li atleha. Mekhoa ea phekolo ea aluminium eo hangata re e bonang e kenyelletsa electrophoresis, anodizing, ho roala phofo, ho roala ha PVDF, lijo-thollo tsa lehong joalo-joalo.

1. Electrophoresis

Electrophoresis ke lesela la electrophoretic holim'a cathode le anode. Tlas'a ketso ea gagamalo, qosoa li-ion barbotage fallela cathode le ho sebelisana le alkalinity generated ka holim'a cathode ho theha lintho tse insoluble, e leng behoa holim'a workpiece. Aluminium profile electrophoresis e bua ka mokhoa oa ho beha motsoako oa aluminium o extruded ka tanka ea electrophoresis, le ho etsa filimi e teteaneng ea resin holim'a metsi ka mor'a ho feta hona joale ka ho toba. Litlaleho tsa aluminium tsa electrophoretic li khanya haholo ebile li na le phello ea seipone, e leng ho ntlafatsang ho hanyetsa ha kutu.

Phallo ea Ts'ebetso:

Electrolysis (ho bola) ➤ Electrophoresis (ho falla, ho falla) ➤ Electrodeposition (pula) ➤ Electroosmosis (dehydration)

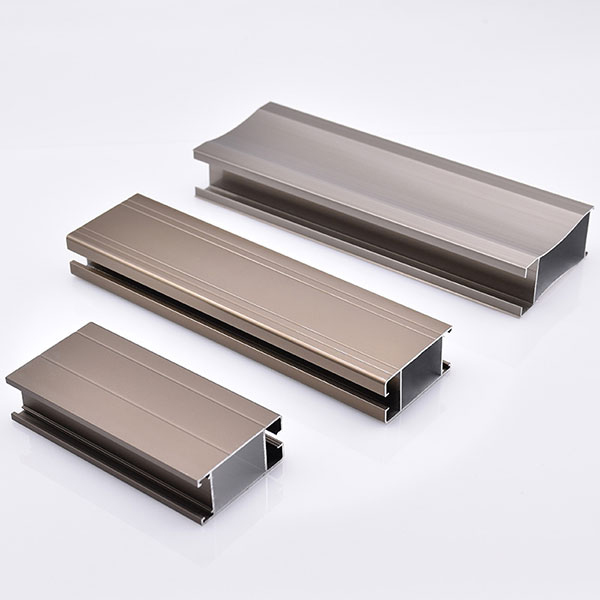

2. Anodizing

Anodized aluminium profiles e bua ka mokhoa oo aluminium le lisebelisoa tsa eona li etsang filimi ea oxide lihlahisoa tsa aluminium (li-anodes) tlas'a electrolyte e lumellanang le maemo a itseng a ts'ebetso tlas'a ts'ebetso ea hona joale e sebelisoang. Leha ho le joalo, filimi ea oxide e entsoeng ka holim'a aluminium ea anodized e fapane le filimi e akaretsang ea oxide, 'me aluminium ea anodized e ka dauoa ka mebala ea electrolytic. E le ho hlola bofokoli ba ho thatafala ha aluminium alloy holim'a, ho hanyetsa ho roala, joalo-joalo, ho atolosa sebaka sa ts'ebeliso, le ho lelefatsa bophelo ba ts'ebeletso, theknoloji ea kalafo ea holim'a metsi e fetohile sehokelo sa bohlokoa sa tšebeliso ea lisebelisoa tsa aluminium, 'me theknoloji ea anodic oxidation hajoale ke eona e sebelisoang haholo le e atlehileng ka ho fetisisa. ea.

Phallo ea Ts'ebetso:

Ho Fokotsa Mocheso ➤ Ho Pholisetsa Lik’hemik’hale ➤ Ho Tšela Asiti ➤ Ho Hlobola Filimi e Ntšo ➤ Anodizing ➤ Kalafo ea Pele ho Tlōla ➤ Ho daea ➤ Ho Tiisa ➤ Ho Omisa

Phapang pakeng tsa anodizing le electrophoresis: anodizing ke oxidized pele ebe e mebala, athe electrophoresis e mebala ka ho toba.

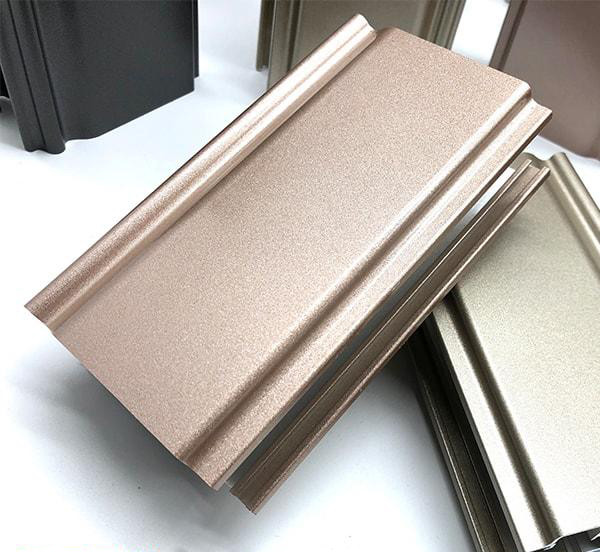

3. Ho roala ka phofo

Sebelisa lisebelisoa tsa ho fafatsa phofo ea electrostatic ho fafatsa seaparo sa phofo holim'a sebaka sa mosebetsi. Tlas'a ketso ea motlakase o tsitsitseng, phofo e tla be e ts'oareloa ka mokhoa o ts'oanang holim'a setsi sa mosebetsi ho etsa seaparo sa phofo. Liaparo tse fapaneng tsa ho qetela. Phello ea ho fafatsa e phahame haholo ho feta mokhoa oa ho fafatsa ka matla a mochine, ho khomarela, ho hanyetsa kutu, le ho hanyetsa botsofali.

Phallo ea Ts'ebetso:

Kalafo e ka holimo ➤ ho fafatsa ➤ pheko ea ho baka

4. Ho roala ha PVDF

PVDF Coating ke mofuta oa ho fafatsa ka electrostatic, eo hape e leng mokhoa oa ho fafatsa ka metsi. Sekoaelo sa setlolo sa fluorocarbon se sebelisitsoeng ke seaparo se entsoeng ka ho baka polyvinylidene fluoride resin e le thepa ea motheo kapa ka tšepe ea aluminium phofo e le 'mala. Ho na le mefuta e emisitsoeng le e emisitsoeng ka halofo. Mofuta o emisitsoeng ke phekolo ea pele le ho fafatsa lisebelisoa tsa aluminium, 'me lisebelisoa tsa aluminium li emisoa nakong ea ho phekola. Seaparo sa boleng bo phahameng ba fluorocarbon se na le tšepe e khanyang, mebala e khanyang le phello e hlakileng ea likarolo tse tharo.

Phallo ea Ts'ebetso:

Mokhoa oa ho alafa pele: ho tlosa le ho silafala ha aluminiamo ➤ ho hlatsoa ➤ ho hlatsuoa ha alkali (ho tlosa oli) ➤ ho hlatsoa ➤ pickling ➤ ho hlatsoa ➤ chromizing ➤ ho hlatsoa ➤ ho hlatsoa metsi a hloekileng

Mokhoa oa ho fafatsa: ho fafatsa primer ➤ topcoat ➤ ho qeta pente ➤ ho baka (180-250℃) ➤ tlhahlobo ea boleng

Phapang pakeng tsa ho fafatsa phofo ea electrostatic le ho fafatsa ha fluorocarbon: ho fafatsa phofo ke ho sebelisa thepa ea ho fafatsa phofo (mochini oa electrostatic spraying) ho fafatsa phofo e koahelang holim'a workpiece. Tlas'a ketso ea motlakase o tsitsitseng, phofo e tla khabisoa ka mokhoa o ts'oanang holim'a sebaka sa mosebetsi ho etsa lera la ho roala phofo. Ho fafatsa ka fluorocarbon ke mofuta oa ho fafatsa ka electrostatic, e leng mokhoa oa ho fafatsa ka metsi. E bitsoa ho fafatsa ka fluorocarbon, 'me e bitsoa oli ea curium Hong Kong.

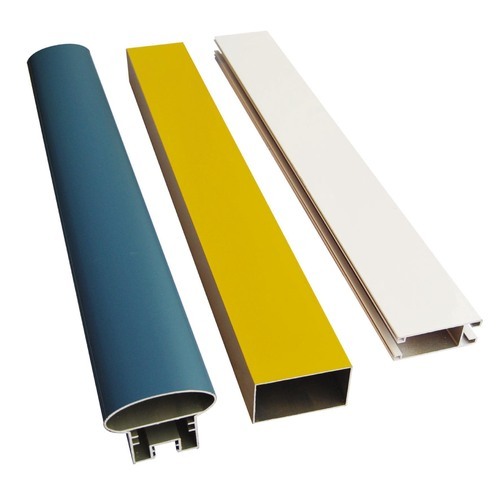

5. Thollo ea Lehong

Profaele ea phetisetso ea lijo-thollo ea lehong e thehiloe holim'a ho fafatsa ka phofo kapa ho penta ka electrophoretic, ho ea ka molao-motheo oa mocheso o phahameng oa sublimation oa ho kenella mocheso, ka ho futhumatsa le khatello, mokhoa oa lijo-thollo oa lehong pampiring ea ho fetisa kapa filimi ea ho fetisa e fetisetsoa ka potlako 'me e phunyeletse Ho profiles tse fafalitsoeng kapa electrophoresis. Sebopeho sa lehong se hlahisoang se na le sebopeho se hlakileng, phello e matla ea mahlakore a mararo, 'me e ka bonahatsa hantle maikutlo a tlhaho a lijo-thollo tsa lehong. Ke lisebelisoa tse ntle tsa ho boloka matla le tikoloho ho nkela lehong la setso sebaka.

Phallo ea Ts'ebetso:

Khetha karoloana ➤ Koahela pampiri ea khatiso ea lijo-thollo tsa lehong ➤ Koahela mokotla oa polasetiki ➤ Phula ➤ Ho baka ➤ Tabola pampiri ea khatiso ➤ Hloekisa bokaholimo

Rui Qifeng e khona ho sebetsana le kalafo e fapaneng e rarahaneng ea holim'a lisebelisoa tsa meralo. Boleng bo phahameng le litheko tse utloahalang, amohela bakeng sa lipatlisiso tse ling.

Guangxi Rui QiFeng New Material Co., Ltd.

Aterese: Pingguo Industrial Zone, Baise City, Guangxi, China

https://www.aluminum-artist.com/

Email :Jenny.xiao@aluminum-artist.com

Nako ea poso: Feb-20-2023