Aluminium extrusion ke ts'ebetso ea tlhahiso e sebetsang hantle haholo le e fapaneng e sebelisoang ho theha likarolo tse nang le li-profiles tse fapaneng tse fapaneng. Bohareng ba ts'ebetso ena ho na le e 'ngoe ea lintlha tsa bohlokoahali:the extrusion die. Sesebelisoa sena se entsoeng ka mokhoa o nepahetseng se bōpa aluminium tlas'a khatello e matla 'me se bapala karolo ea bohlokoa ho khetholla boleng ba sehlahisoa, bokaholimo ba bokaholimo le ho nepahala ha boholo ba sehlahisoa.

Aluminium Extrusion Die ke Eng?

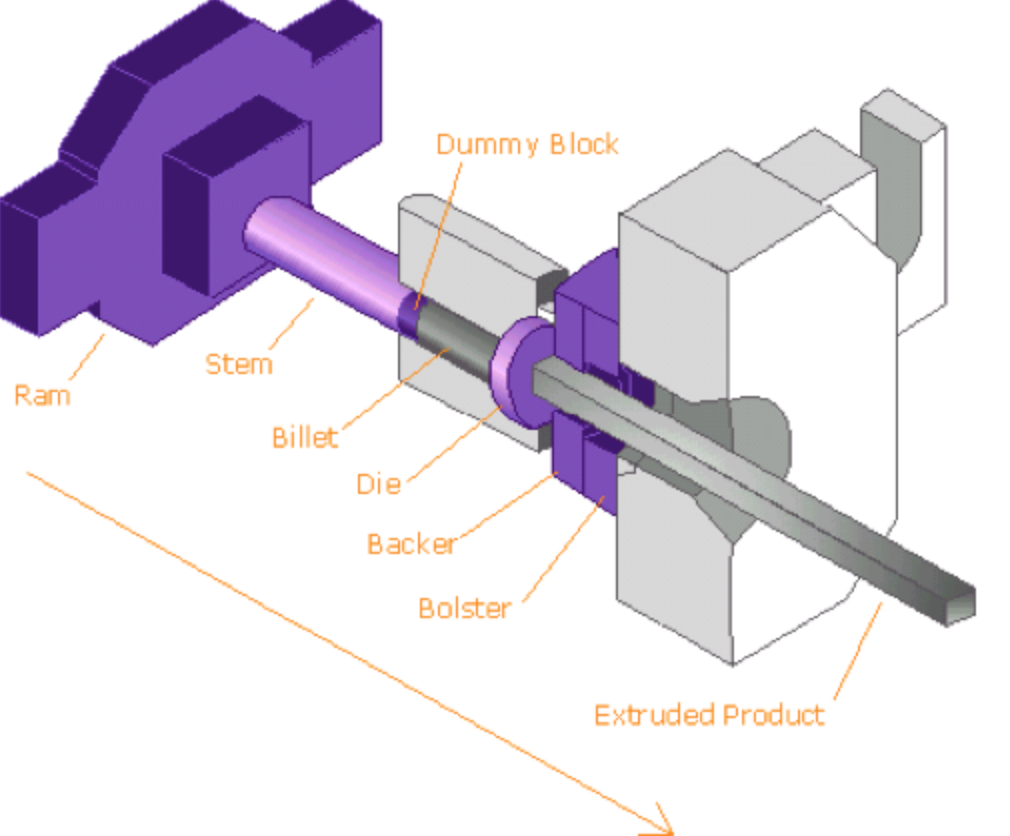

An extrusion die ke sesebelisoa sa tšepe se entsoeng ka ho khetheha se nang le ntho e itsengshoa ho bulae etsang aluminium ha e ntse e phunyeletsoa tlas'a khatello e phahameng. Hammoho le lisebelisoa tsa ts'ehetso tse kang li-backers, li-bolster, le li-sub-bolster, lefu le tiisa ho lumellana hantle le botšepehi ba sebopeho nakong ea extrusion.

Mefuta ea Extrusion E Shoa

Extrusion dies e arotsoe ka mefuta e meraro ea mantlha ho ipapisitsoe le jiometry ea boemo bo lakatsehang:

1. Tiileng E Shoa

E sebelisetsoa ho hlahisa li-profile ntle le li-cavities - joalo ka li-bar, li-angles, kapa likanale.

● Likaroloana:

○ Letlapa la Die: E na le orifice e bōpehileng bakeng sa boemo ba ho qetela.

○Letlapa la Backer: E fana ka tšehetso ka mor'a lefu.

○Letlapa la ho fepa (ho ikhethela): E thusa ho tataisa phallo ea thepa.

2. Sekoti se Shoa

E etselitsoe li-profiles tse nang le li-void tsa kahare joalo ka li-tubes kapa liforeimi tsa lifensetere.

●Likaroloana:

○Mandrel (kapa konokono): E etsa sekoti se ka hare.

○Die Cap: E etsa sebopeho sa ka ntle mme e tšoara mandrel sebakeng sa eona.

○Motšehetsi: E fana ka tšehetso ea meralo le taolo ea mocheso.

3. Semi-Hollow Shoes

E sebelisoa bakeng sa liprofaele tse nang le li-void tse koetsoeng - ho kopanya likarolo tsa likarolo tse tiileng le tse se nang letho. Tsena li loketse li-geometri tse rarahaneng tse nang le botenya bo fapaneng ba marako.

Mokhoa oa Extrusion le Mosebetsi oa Die

Mehato ea bohlokoa ea extrusion e kenyelletsa:

1.Billet Preheating:

Li-billet tsa aluminium li futhumatsoa pele ho 370-500 ° C (700-930 ° F) ho ntlafatsa polasetiki.

2.Loading & Extrusion:

Billet e kenngoa ka har'a setshelo, 'me pheleu ea haeteroliki (e nang le khatello ho tloha ho lithane tse 1,000 ho isa ho tse 15,000) e e sutumetsa ka har'a lefi.

3.Sebopeho sa Boemo:

Aluminium e nka sebopeho sa thipa ha e tsoa, e etsa profil e hlokahalang.

4.Ho Pholisa, Ho Seha le ho Qetella:

Li-profile lia pholile, lia otlolloa, li khaoloa ka bolelele, 'me li ka qetella li felile joalo ka anodizing kapa ho roala phofo.

Ts'ebetsong ena eohle,lefu le tiisa hore sebopeho se nepahetse, boleng ba holim'a metsi, le ho tsitsa.

Mamello e Amanang le Lefu le Taolo ea Botenya ba Marako

Ho nepahala ho bohlokoa. Mamello ea aluminium extrusion e itšetlehile ka:

●Boemo ba profaele le ho rarahana

●Botenya ba lebota(marako a masesaane haholo a eketsa bothata)

●Ho apara ka nako e telele

●Botenya ba lebotae ka fapana hanyane, haholo ho li-dies e ncha - li-extrusions tsa pele li kanna tsa ba tšesaane hanyane, empa ha li sebelisoa, li shoa li tsitsitse 'me li lumellana hantle le moralo oa lebitso. Ke ka lebaka lenalihlopha tse latelanghangata e bonts'a liphetho tse teteaneng le tse tsitsitseng haholoanyane.

Mamello e tloaelehileng e laoloa ke litekanyetso tsa machaba tse kangEN 755-9kapaAA (Aluminium Association)litlhaloso.

Die Surface Phekolo le Tlhokomelo

Ho ntlafatsa ts'ebetso le nako ea bophelo, extrusion e shoa hangata e etsoa:

Nitriding

Ts'ebetso ea ho thatafatsa ka holim'a metsi e jalang naetrojene ka har'a sehatsetsing, e eketsang ho thatafala le ho hanyetsa - ho bohlokoa bakeng sa ho sebetsana le khatello e phahameng le mocheso.

Die Preheating (Die Cooking)

E boetse e tsejoa e le “煲模(bao mo)” ka Sechaena, mokhoa ona butle-butle o futhumatsa lefi pele ho extrusion ho fokotsa tsitsipano ea mocheso le ho ntlafatsa ts'ebetso ea tšepe.

Mathata a Tloaelehileng a Lefu le Mekhoa ea Thibelo

✅ Ho Sebetsa le ho Tala

Khatello e phahameng le mocheso li baka ho apara butle-butle.Ho hlahloba khafetsa, ho bentša bocha, le ho hlabolla bochalelefatsa bophelo ba lefu.

✅ Litšitiso tse kaholimo

Mehopo, mela e qollang, kapa li-buildup li ka ama boleng ba bokaholimo. Tloaeloho hloekisa lefulemekhoa ea phekolo ea holimothusa ho fokotsa mefokolo.

✅ Tsamaiso ea Thermal

Ho futhumatsa kapa ho tsidifala ho sa leka-lekaneng ho lebisa ho sekoli kapa ho senyeha ha lefu. Insulation e nepahetseng le preheating e laoloang ke ea bohlokoa.

✅ Ho tsamaisana le Tšehetso

Ho se tsamaisane hantle ho baka liphoso tsa maemo le ho hloleha ho shoa kapele. Nako le nakotekanyetso bochaletlhokomeloli bohlokoa bakeng sa ho nepahala.

Hobaneng ho E-shoa ho Bohlokoa ho Aluminium Extrusion

Extrusion e entsoeng hantle, e hlokometsoeng hantle e na le phello e tobileng:

●Ho nepahala ha dimensional

●Ho rarahana ha profil

●Lebelo la extrusion

●Qetello ea bokaholimo

●Kakaretso ea theko ea sehlahisoa le ho tsitsa

Ho khetha mofuta o nepahetseng oa lefu, ho utloisisa taolo ea botenya ba marako, le ho kenya ts'ebetsong mekhoa e matla ea ho thibela ho lokisoa ke tsa bohlokoa bakeng sa ho finyella liphello tse tsitsitseng, tsa boleng bo phahameng.

U Batla Molekane ea Tšepahalang oa Custom Die & Extrusion?

Ho [Lebitso la K'hamphani ea Hao], re ipabola ka ho nepahala ha aluminium extrusion mme re fana ka tšehetso e felletseng bakeng sants'etsopele ea lefu la moetlo, ho ntlafatsa boemo, letsamaiso ea lefu la bophelo. Hore na o hlahisa liprofaele tse tiileng, tse se nang letho, kapa tse rarahaneng, sehlopha sa rona sa boenjiniere se ikemiselitse ho u thusa ka leseli la litsebi le tlhahiso e tšepahalang.

Ikopanye le rona kajenoho ithuta haholoanyane ka hore na re ka etsa hore meralo ea hau e phele joang ka tharollo e nepahetseng ea extrusion.

Lengolo-tsoibila: will.liu@aluminium-artist.com

Webosaete: www.aluminium-artist.com

Aterese:Pingguo Industrial Zone, Baise City, Guangxi, China

Nako ea poso: Jun-17-2025